Spray drying is an advanced process for transforming liquid feed into dry, powdery products. Among the various spray dryer configurations, the Horizontal Spray Dryer offers a unique design tailored for compact setups and short drying times. Its efficient layout and adaptability make it a preferred choice for industries requiring consistent drying performance within limited spaces.

In this blog, we’ll explore:

- How Horizontal Spray Dryers work.

- Key benefits of their design.

- Applications in diverse industries.

- Expert tips to optimize performance.

What is a Horizontal Spray Dryer?

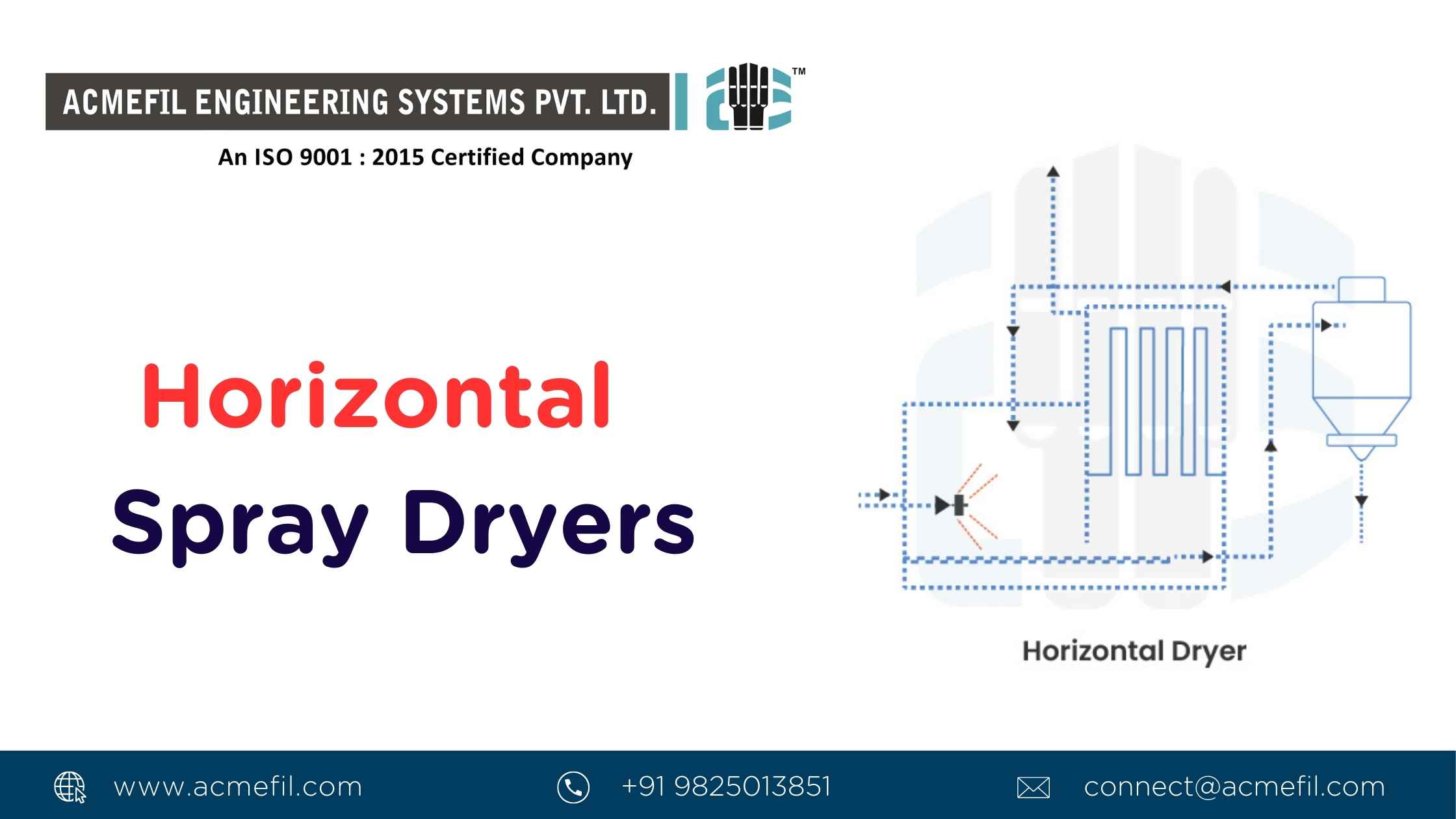

A Horizontal Spray Dryer features a drying chamber with a rectangular or “V” shape bottom. Unlike vertical dryers, the feed spray in horizontal dryers is introduced horizontally into the chamber, and the dried particles settle at the bottom. The unique configuration ensures efficient drying within a smaller footprint, making it ideal for industrial setups where space is a constraint.

How Does a Horizontal Spray Dryer Work?

- Feed Atomization

Liquid feedstock is atomized into fine droplets using rotary or pressure nozzles, which spray horizontally into the drying chamber. - Hot Air Inflow

Heated air is introduced into the chamber, flowing across the sprayed droplets to evaporate moisture. - Drying Process

The droplets rapidly lose moisture as they travel through the chamber. The dried particles settle at the chamber’s bottom due to gravity. - Separation and Collection

The dried powder is collected using a sweep conveyor or screw conveyor, while fine particles are separated through bag filters or cyclones. - Exhaust Air Release

Moisture-laden air is vented out through an exhaust system.

Key Benefits of Horizontal Spray Dryers

1. Compact Design

The horizontal layout requires less vertical space, making it ideal for facilities with height constraints.

2. Efficient Drying Process

The horizontal airflow and particle settling system ensure rapid drying, reducing processing time.

3. Customizable Configurations

Available with flat or “V” shaped bottoms, the design can be tailored to specific product and process requirements.

4. Energy Efficiency

Optimized airflow and efficient heat transfer minimize energy consumption while maintaining product quality.

5. Ease of Maintenance

The horizontal design simplifies access for cleaning and maintenance, ensuring consistent performance.

Applications of Horizontal Spray Dryers

Horizontal Spray Dryers are versatile and cater to a wide range of industrial applications.

1. Food and Beverage Industry

- Drying coffee, tea, and powdered beverages.

- Preserves flavor and aroma while ensuring uniform particle sizes.

2. Pharmaceutical Industry

- Producing heat-sensitive APIs and excipients.

- Ensures consistent particle size and stability for formulations.

3. Chemical Industry

- Drying catalysts, polymers, and specialty chemicals.

- Provides precise particle distribution and high-quality output.

4. Nutraceuticals

- Drying vitamins, probiotics, and herbal extracts.

- Ensures preservation of active compounds for enhanced efficacy.

5. Agriculture and Animal Feed

- Drying feed additives and supplements.

- Produces durable and easy-to-handle powders.

How Horizontal Spray Dryers Compare to Vertical Spray Dryers

| Feature | Horizontal Spray Dryer | Vertical Spray Dryer |

|---|---|---|

| Chamber Shape | Rectangular or “V” shaped | Cylindrical with cone bottom |

| Space Requirement | Compact, suitable for low ceilings | Requires significant vertical height |

| Drying Time | Shorter due to horizontal airflow | Longer due to vertical air circulation |

| Ideal Applications | Compact setups, rapid drying | High-capacity production |

| Maintenance | Easy access for cleaning | More complex to maintain |

Expert Tips for Optimizing Horizontal Spray Dryers

- Monitor Airflow and Temperature

Ensure optimal airflow and maintain consistent air temperature for uniform drying. - Optimize Feed Properties

Control feed viscosity and solid content for efficient atomization and drying. - Regular Maintenance

Clean conveyors, nozzles, and filters regularly to prevent clogs and maintain performance. - Invest in Advanced Separation Systems

Use high-quality cyclones or bag filters to maximize powder recovery and minimize waste. - Configure the Bottom Design

Choose a flat or “V” shaped bottom based on the product’s flow and settling characteristics.

Why Choose Horizontal Spray Dryers?

The Horizontal Spray Dryer combines compact design, efficient drying, and ease of operation. Its ability to handle diverse feedstocks while optimizing space usage makes it a valuable asset for industries with limited vertical space or those requiring rapid drying solutions.

Whether you’re processing food, pharmaceuticals, or chemicals, a Horizontal Spray Dryer delivers consistent quality, high energy efficiency, and unmatched reliability.

Conclusion

The Horizontal Spray Dryer is a versatile and efficient drying solution tailored for industries requiring compact setups and precise drying performance. With its innovative design and robust features, it ensures consistent results while optimizing operational costs.

Acmefil Engineering Systems Pvt. Ltd. is a premier spray dryer manufacturer, delivering innovative and reliable drying solutions to industries worldwide. With over two decades of expertise, Acmefil designs and manufactures cutting-edge spray dryers tailored to the unique needs of the food, pharmaceutical, and chemical sectors. Our ISO 9001:2015-certified systems are renowned for their precision, energy efficiency, and exceptional performance. Backed by advanced technology, expert engineers, and a commitment to quality, Acmefil is the trusted partner for businesses seeking high-quality spray drying equipment to optimize production and ensure superior product quality.